-

PHBN-Series

Heater Blower None Purge Type

히터블로워 넌퍼지 흡착식 에어드라이어

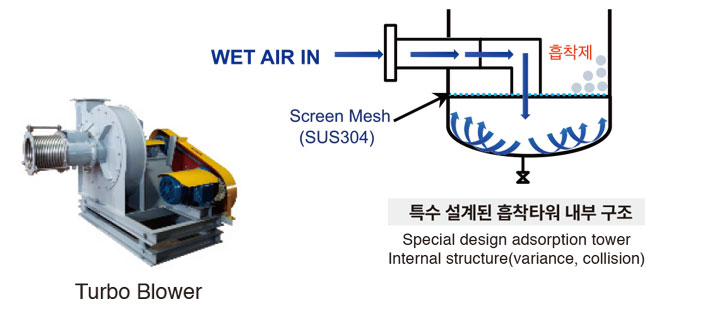

흡착제 재생 공정 (히팅과 쿨링) 시 모두 블로워를 이용하여 압축공기 소모가 전혀 없으며 특수설계된 흡착타워 내부 구조는 다량의 입구 측 수분을 매우 효과적으로 제거한 후 흡착타워로 보내기 때문에 전기히터와 블로워 전력비를 최대한 절감할 수 있습니다.

In both the adsorbent regeneration process (heating and cooling), there is no compressed air consumption using the blower, and the specially designed adsorption tower internal structure removes a large amount of moisture from the inlet side and sends it to the adsorption tower.

-

-

설계특징

노점 향상과 흡착제 수명 연장을 위한 타워 구조

Tower structure for improving dew point and extending adsorbent life

최적의 설정온도에 따른 재생 공정으로 에너지 절감

Energy saving by renewable process according to optimal set temperature

유량 변동에도 안정적인 이슬점 제공

Provides stable dew point for flow rate changes

-

DESIGN CONDITION

Design Pressure : 9.7 bar (Standard)

Max. Air Inlet Temperature : 40℃

Operating Cycle : 10.0 Hrs

Dewpoint : -40℃ (std.)

TECHNICAL SPECIFICATIONS

가로 화면을 왼쪽으로 밀어서 전체 내용 보실 수 있습니다.

가로 화면을 왼쪽으로 밀어서 전체 내용 보실 수 있습니다.

| Model | Flow Capacity | Electric Heater | Blower | Adsorbent | Connection | Dimension | Weight |

|---|---|---|---|---|---|---|---|

| ( Nm³/hr ) | ( KW ) | (HP) | 2-tower ( Kgs ) | L×W×H ( mm ) | ( Kgs ) | ||

| PHBN - 2400 | 2,400 | 28.0 | 7.5 | 1,000 | 80A(F) | 2,700 × 1,700 × 2,500 | 2,500 |

| PHBN - 3200 | 3,200 | 38.0 | 10 | 1,500 | 100A(F) | 2,800 × 1,800 × 2,600 | 3,000 |

| PHBN - 3900 | 3,900 | 46.0 | 10 | 1,800 | 100A(F) | 2,800 × 1,800 × 2,600 | 3,000 |

| PHBN - 4700 | 4,700 | 55.0 | 15 | 2,000 | 125A(F) | 3,200 × 2,000 × 2,650 | 4,100 |

| PHBN - 5500 | 5,500 | 65.0 | 15 | 2,300 | 150A(F) | 3,800 × 2,400 × 2,700 | 5,9000 |

| PHBN - 6300 | 6,300 | 76.0 | 15 | 2,800 | 150A(F) | 4,000 × 2,400 × 2,800 | 6,500 |

| PHBN - 7000 | 7,000 | 80.0 | 20 | 3,200 | 150A(F) | 4,100 × 2,500 × 2,900 | 7,000 |

| PHBN - 8000 | 8,000 | 90.0 | 20 | 3,600 | 150A(F) | 4,200 × 2,600 × 3,000 | 7,900 |

| PHBN - 9000 | 9,000 | 100.0 | 20 | 4,000 | 200A(F) | 4,300 × 2,700 × 3,000 | 8,800 |

| PHBN - 10000 | 10,000 | 110.0 | 30 | 4,600 | 200A(F) | 4,400 × 2,800 × 3,200 | 10,000 |

| PHBN - 12000 | 12,000 | 120.0 | 30 | 5,400 | 250A(F) | 4,600 × 2,800 × 3,400 | 11,000 |

| PHBN - 14000 | 14,000 | 130.0 | 40 | 6,000 | 250A(F) | 4,800 × 3,000 × 3,400 | 13,500 |

| PHBN - 15000 | 15,000 | 140.0 | 50 | 6,800 | 250A(F) | 5,000 × 3,100 × 3,400 | 15,000 |

| PHBN - 18000 | 18,000 | 170.0 | 50 | 8,600 | 250A(F) | 5,400 × 3,400 × 3,600 | 18,000 |

1. 쿨러 냉각장치는 수냉식이 표준사양으로 냉각수가 공급이 안될 시에는 공냉식으로 제작 가능합니다. (구성도 변경)

The cooler cooling system can be manufactured air-cooled if the water cooling system is standard and the cooling water is not supplied (Change the p & id).

2. 노점계를 설치하여 노점제어 운전을 하면 보다 경제적으로 설비를 운영할 수 있습니다.

If you install a dew point meter and operate the dew point operating control, you can operate the facility more economically.

3. 터치모니터 제어 방식을 주문하시면 스마트 운전 지원이 가능하며 보다 쉽게 운전 상황을 판독할 수 있습니다.

If you order a touch monitor control method, you can support smart operation and read the operation status more easily.

* 주의사항 : 상기 사양은 예고없이 변경될 수 있으니 사전에 문의하시기 바랍니다. Caution : Please contact us in advance as the above specifications may be changed without notice.