-

PMF-Series

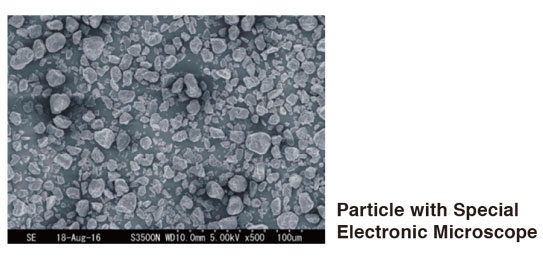

For Ultra-fine Particle Removal

초미립 파티클 제거용 멤브레인 필터

모든 제품은 전해연마(EP) 처리를 하며 벨로즈 밸브를 부착하여 주기적인 파티클 측정을 용이하게 제작하였습니다.

All products are treated with electrolytic polishing(ep). Periodically by attaching the valve of the valve fabricated to facilitate particle measurement. Periodically attach the bellows valve to the outlet side. Fabricated to facilitate particle measurement.

설계특징

파티클 제거 능력과 신뢰성이 증명된 카트리지 적용

Apply a cartridge with proven particle removal capability and reliability

최소한의 차압을 생각한 카트리지 적용과 개별 성적서 제공

Apply cartridges with minimal differential pressure and provide individual reports

분리 조립이 용이한 카트리지 지지 구조

Easy to disassemble cartridge support structure

-

STANDARD DESIGN

Inlet Pressure & Temperature : 7.0 barG, 40℃

Differential Pressure : max. 0.2 barG

Standard Filteration : 0.01 micron

Standard Particle Warranty : Not more than 10, 0,1 microns / 1 CFM

TECHNICAL SPECIFICATIONS

가로 화면을 왼쪽으로 밀어서 전체 내용 보실 수 있습니다.

가로 화면을 왼쪽으로 밀어서 전체 내용 보실 수 있습니다.

| Model | Flow Capacity | Cartridge Q.ty | Dimension | Weight |

|---|---|---|---|---|

| ( Nm³/hr ) | L×W×H ( mm ) | ( Kgs ) | ||

| PMF - 15A | 1.5 | 1 | 260 × 520 | 14 |

| PMF - 20A | 2.0 | 1 | 280 × 520 | 15 |

| PMF - 25A | 4.0 | 1 | 280 × 520 | 34 |

| PMF - 40A | 8.0 | 1 | 350 × 1,060 | 38 |

| PMF - 50A | 12.0 | 1 | 360 × 1,060 | 40 |

| PMF - 65A | 24.0 | 2 | 500 × 1,350 | 140 |

| PMF - 80A | 36.0 | 3 | 510 × 1,470 | 190 |

| PMF - 100A | 60.0 | 5 | 600 × 1,500 | 230 |

| PMF - 125A | 72.0 | 6 | 620 × 1,300 | 250 |

| PMF - 150A | 108.0 | 9 | 740 × 2,100 | 330 |

| PMF - 200A | 192.0 | 16 | 1,000 × 2,500 | 500 |

1. 설계 표준 재질은 SUS316L이며 테프론 가스켓이 조립됩니다.

The design standard material is SUS316L and the teflon gasket is assembled.

2. 기타 고객의 요구에 따라 설계, 제작이 가능합니다.

Design and manufacture is possible according to other customer's needs.